The thermal analysis unit includes:

- Thermo gravimetric Analysis (TGA).

- FT-IR microscopy.

- FT-IR Microscopy Combined with TGA System (TGA-IR).

- Differential Scanning Calorimetry (DSC).

- Differential/Thermal Mechanical Analysis (DMA).

Thermal analysis unit can be used to identify wall painting degradation, binding media, metals, metal alloys, metallic corrosion, ceramics, glass archaeometry, polymer, plastic and composites, archaeological soil, pottery, ceramics, buried archaeological remains, nanomaterial, DNA, RNA, protein, bones, pigments, and dyes.

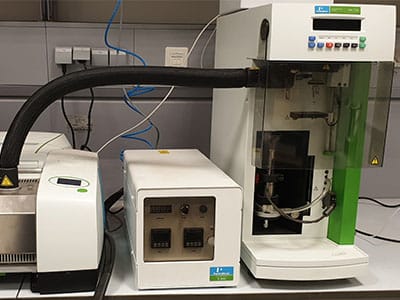

Thermo gravimetric Analysis (TGA)

TGA measures the weight change of a sample as a function of temperature. It can be used to determine weight loss with temperature, thermal stability, and thermo gravimetric kinetics.

FT-IR microscopy

FTIR microscopy has the ability to capture images of large sample areas rapidly at high spatial resolution. It also has the capabilities of intelligent automation and sophisticated analysis. It incorporates a number of unique productivity tools and features, such as an ATR imaging system that enables the collection of high-resolution infrared images of extremely small samples to visualize the composition of materials based on FT-IR spectral data. It can be used in material analysis, forensics, pharmaceuticals, biomedical research, biomaterials, and academic research.

FTIR Microscopy combined with TGA System (TGA-IR)

TGA-IR can analyze polymeric materials, fire retardant polymers, and the enhanced correlation between weight loss and polymer structure. Its applications include the analysis of coal decomposition and pharmaceuticals, where it can be used to better identify bonded and free water in pharmaceuticals. It also has the ability to form quantitative and qualitative analyses without the need for a standard.

Differential Scanning Calorimetry (DSC)

DSC measures the energy absorbed or released from a sample as a function of time or a temperature profile. It is used to recognize organic compounds and polymers. Its applications include measuring glass transition, heat capacity, melting points, and purities.

Differential/Thermal Mechanical Analysis (DMA)

DMA provides easy access to, and mounting of, samples; rapid changing of samples and clamps (typically less than 2 minutes); immersion experiments in any geometry; and optimal analysis head configuration for virtually any test type and sample geometry. It can be used for moisture-induced phase transitions; moisture-sensitive materials like paper, natural fibers, and food products; swelling, shrinking and stiffness changes as humidity changes; also plasticizing and Tg effects as seen in nylon and polyurethanes.